ASA Filament, 3D4Makers

ASA (Acrylonitrile-Styrene-Acrylate) Filament The 3D4MAKERS ASA Filament will be delivered in a vacuum packaging in our recyclable box. Technical information: Acrylonitrile-Styrene-Acrylate (ASA) polymers are amorphous and have mechanical properties similar to those of ABS plastics. However, the ASA properties are far less affected by outdoor weathering. The outstanding weather resistance abilities of ASA is due to the acrylic ester elastomer. ASA parts have good chemical and heat resistance, and high impact strength, even at low temperatures. Typical ASA applications are buiding/construction, automotive and recreation parts. Measurements & Tolerance Size Diameter tolerance roundness 1,75 mm Filament +/- 0,05mm 95% 2,85 mm Filament +/- 0,10mm 95% Physical properties Description Value Test method Density 1,07 g/cm3 ASTM D792 Melt Mass-Flow Rate (MFR) (220ᵒC/10KG) 12 g/10 min ASTM D1238 Mechanical properties Description Value Test method Tensile Stress 47 Mpa ASTM D638 Flexural Modulus 2210 Mpa ASTM

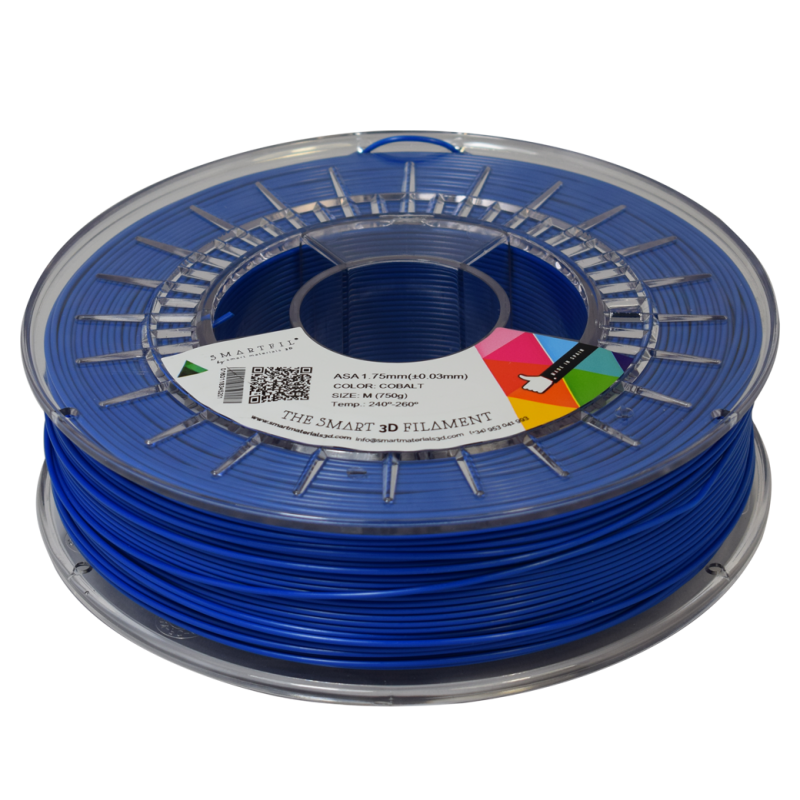

ASA (Acrylonitrile-Styrene-Acrylate) Filament

The 3D4MAKERS ASA Filament will be delivered in a vacuum packaging in our recyclable box.

Technical information:

Acrylonitrile-Styrene-Acrylate (ASA) polymers are amorphous and have mechanical properties similar to those of ABS plastics. However, the ASA properties are far less affected by outdoor weathering. The outstanding weather resistance abilities of ASA is due to the acrylic ester elastomer. ASA parts have good chemical and heat resistance, and high impact strength, even at low temperatures. Typical ASA applications are buiding/construction, automotive and recreation parts.

Measurements & Tolerance

Size

Diameter tolerance

roundness

1,75 mm Filament

+/- 0,05mm

95%

2,85 mm Filament

+/- 0,10mm

95%

Physical properties

Description

Value

Test method

Density

1,07 g/cm3

ASTM D792

Melt Mass-Flow Rate (MFR) (220ᵒC/10KG)

12 g/10 min

ASTM D1238

Mechanical properties

Description

Value

Test method

Tensile Stress

47 Mpa

ASTM D638

Flexural Modulus

2210 Mpa

ASTM D790

Impact strength Notched Izod

180 j/m

ASTM D256

Rockwell Hardness (R-Scale)

103

ASTM D785

Printer settings

Description

Value

Printer nozzle temperature

240 - 280°C

Heated bed temperature

90 - 110°C

Bed Adhesion

Magigoo Original on glass or a PEI Sheet

To get the best results while printing we advise you to keep the 3D printer in a room where there is hardly any draft and/or temperature fluctuations. Keep the 3D printer out of the sun. This cannot be a room where people sleep.

When the 3D printer is not being used it is important to keep the 3D4MAKERS ASA Filament in a bag and stored in a cool, dry and dark place until it is used again.

3DGence Consumables - Additive-X

3D4Makers PCL Filament PCL 99 1.75 mm - 3D Compare Materials

, PEKK-A Filament (PolyEtherKetoneKetone) is high performance 3D printing optimised material with great processability. This material is a member

PEKK-A Filament

The Polyimide (TPI) Z2 filament has now officially received the EN 455

3D Filaprint ASA X - 3D FilaPrint

PEI Ultem 9085 Filament, 3D4Makers

, Facilan™ HT is a high glass transition temperature amorphous co-polyester. , High Tg Copolyester (100°C), superior to PETG and PLA, High tensile

Facilan™ HT Filament

High Quality Filaments PEEK, PEKK, PEI, PPSU, PCL, PETG, ABS, PLA, C8

ASA Filament 3D Printing Material Market - Forecasts from 2022 to 2027

iMakr 3D4Makers Filament